The Ultimate piping solution: Long service life, Maintenance-free high durability, and Lightweight/Compact design

-

Hydrogen Gas and Liquefied Hydrogen Piping

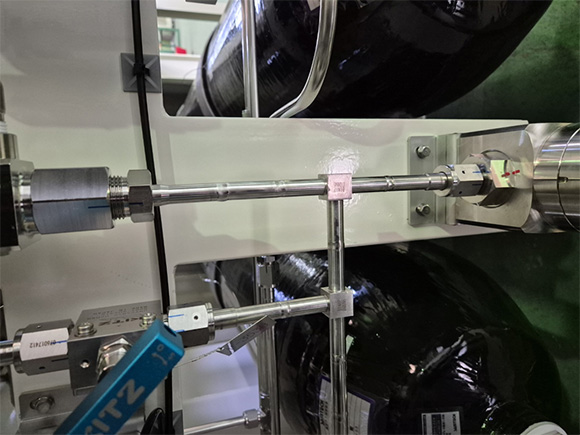

- Ultra-high pressure hydrogen gas piping using HYDREXEL™ (HRX19®) tube

- Vacuum double-layer pipe for transporting liquefied hydrogen

- Applications: Hydrogen gas charging station, long-life hydrogen gas piping (hydrogen vehicles, hydrogen fuel-powered ships)

-

Semiconductor Field

- Vacuum Piping and Bellows Manufacturing

- Semiconductor Equipment (Gas Cabinet, Gas Scrubber)

- Construction of Semiconductor Manufacturing Line (Special Gas)

-

Nuclear power plant piping

{cfg_site.compName}의 제품 개발 및 순서도

고객니즈 품질보증

-

- 고객

- 개발

- 설계

- 고객샘플

TEST - 제품제작

- 시험 제작 및

내부 TEST - 양산

제조 - 검수 및

출하

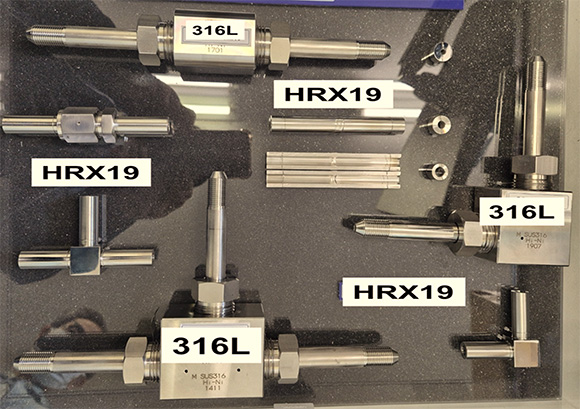

Lightweight/compact effect of HYDREXEL™ (HRX19®) welded pipe

| ½" Tube | STS 316L (Cone &Thread) |

HYDREXEL™ Welded | Weight | |

|---|---|---|---|---|

| Weight(g) (In case of Japan) |

Elbow | 1,224 | 95 | < 8% |

| Tee | 1,606 | 116 | ||

Chemical Composition of HRX19® (%)

(Optimized for Cr, Ni, Mo, Nb, V composition range of ASTM XM19)

※ You can see more content by scrolling left and right.

| Element | C | Si | Mn | P | S | Ni | Cr | Mo | V | Nb | N |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni equivalent ≥ 32.09 | 0.005~0.060 | 0.20~1.00 | 4.30~6.00 | 0.030max. | 0.001max. | 12.0~13.5 | 21.5~23.5 | 1.50~3.00 | 0.15~3.00 | 0.15~0.30 | 0.25~0.40 |

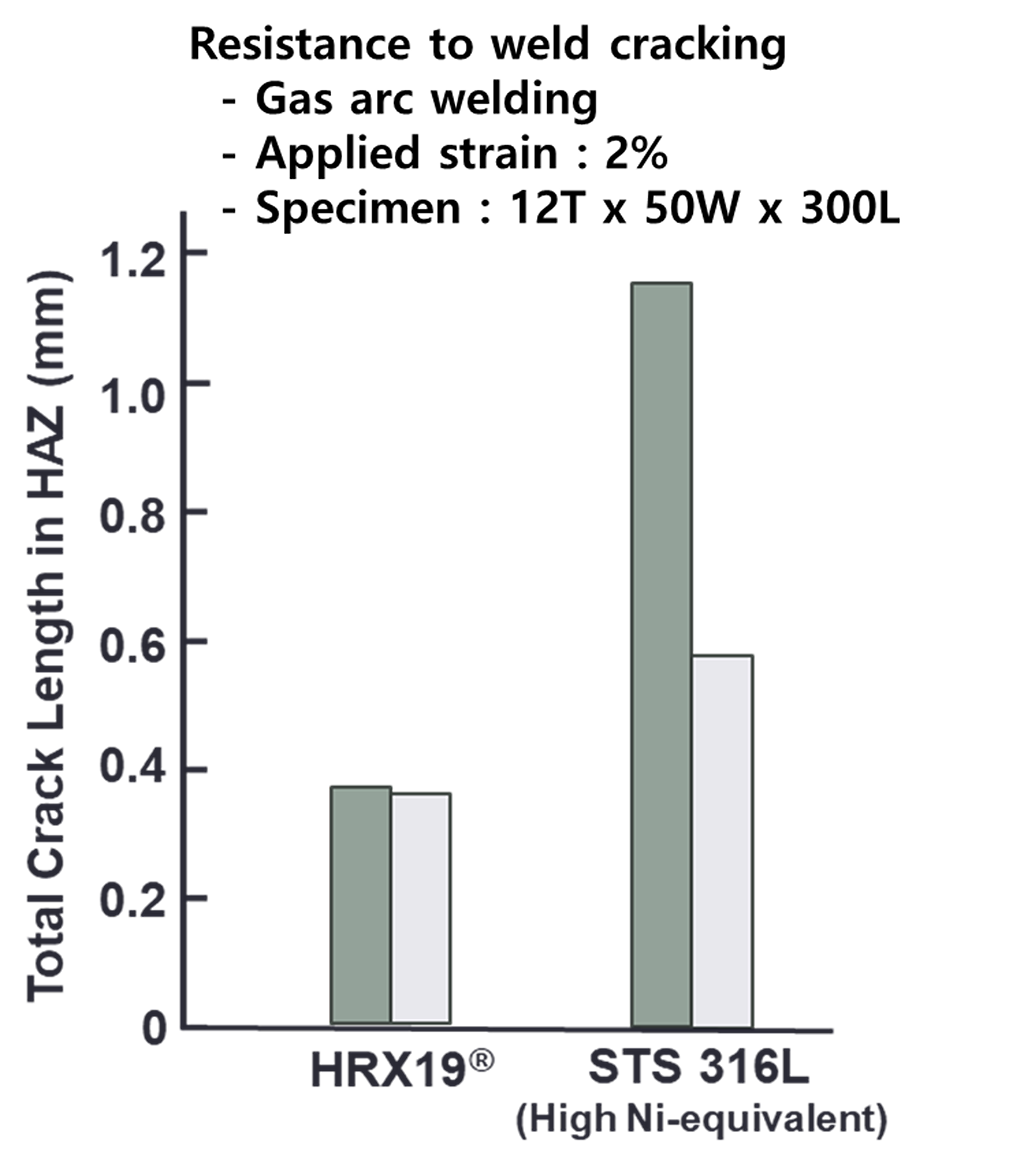

HRX19® Weldability

- Minimum threaded connection

- No tube thickness required for thread formation

- Same outer diameter: Large inner diameter and lightweight/compact tube

- High cost-effectiveness and safety in piping construction

- No gas leakage -> Reduced maintenance/repair costs

Special features of HYDREXEL™ (HRX19®) material

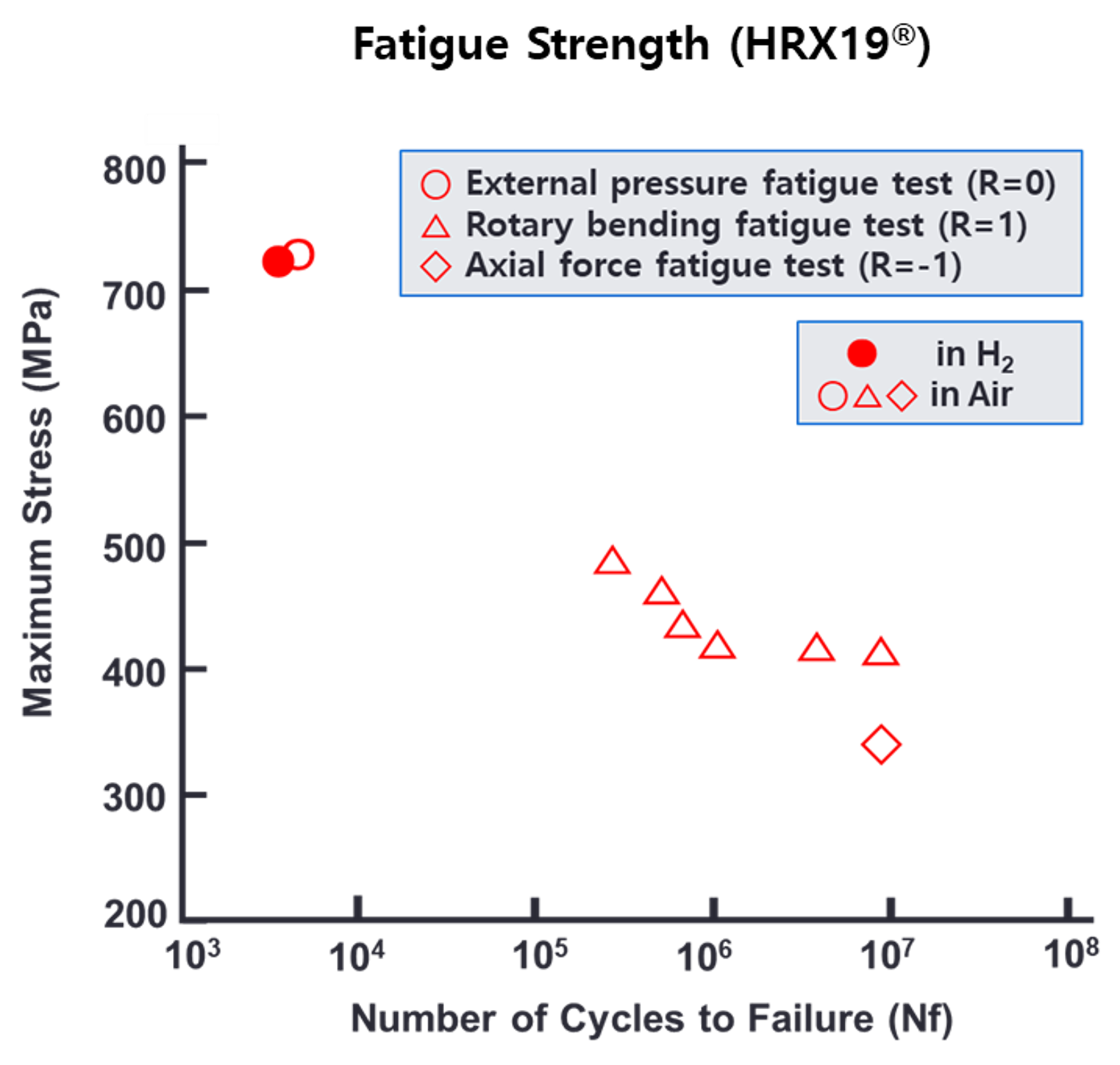

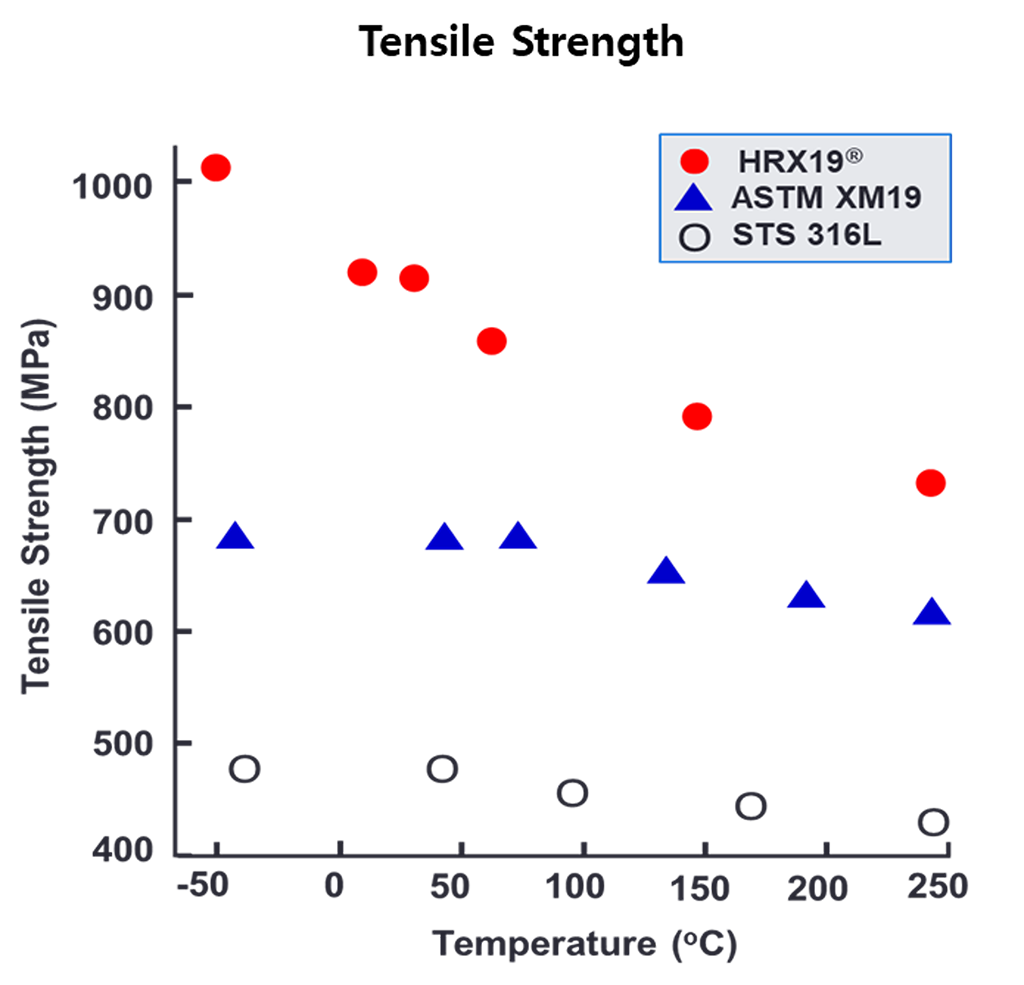

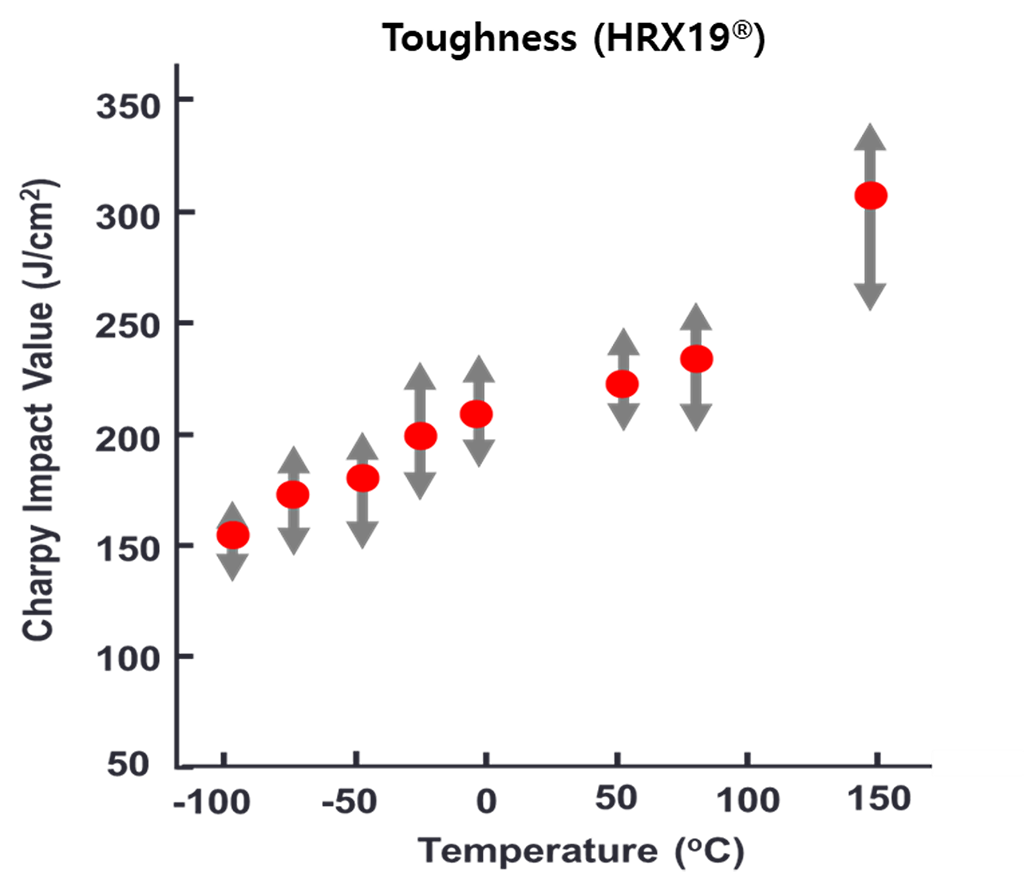

HRX19® Tensile Strength and Toughness

- Safe operation and ultra-high pressure/rapid charging possible

- Thin wall tube: compact/light weight and reduced material cost

- Rapid charging of ultra-high pressure hydrogen gas required by US DOE possible (5kg hydrogen gas charging in 200 seconds)

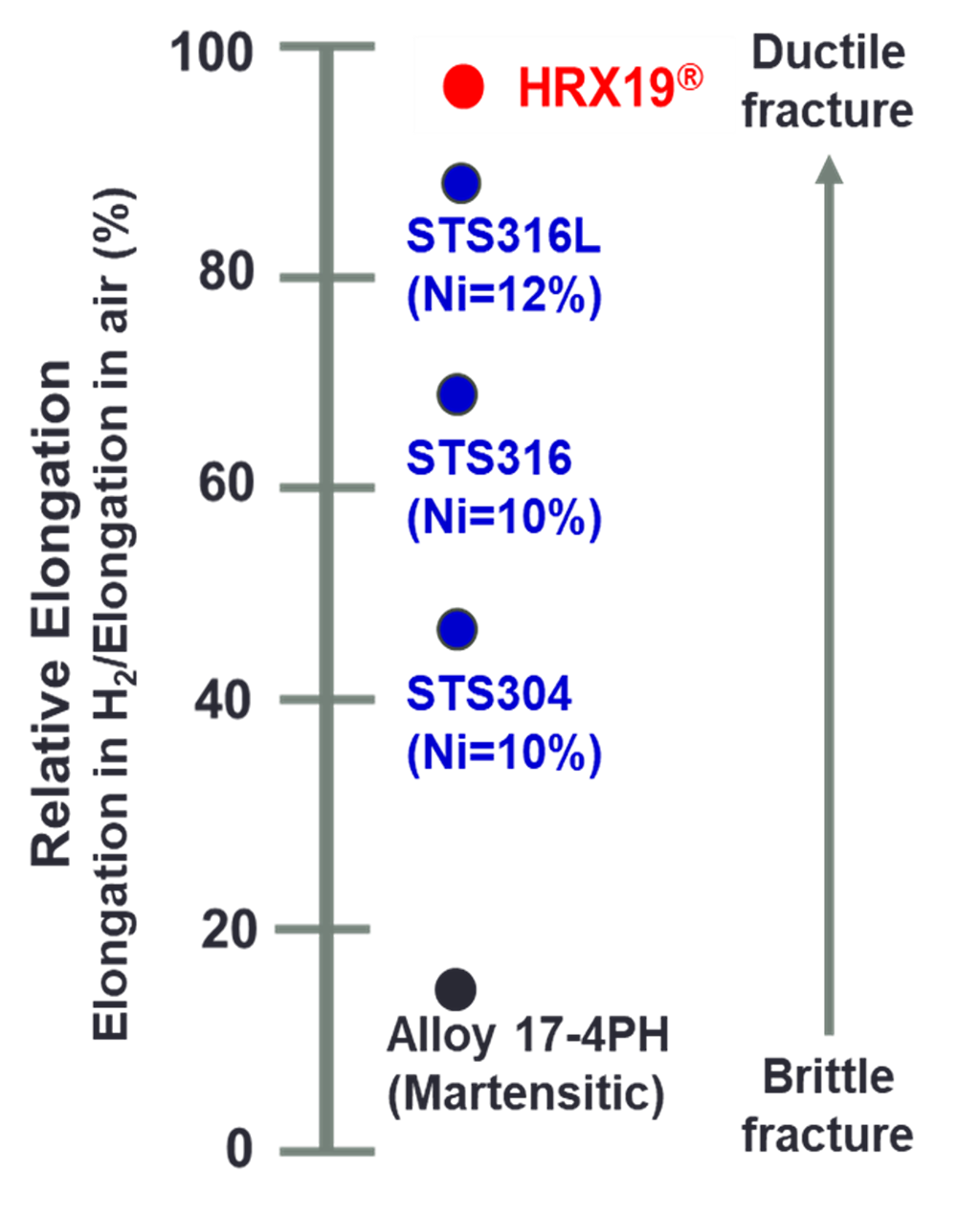

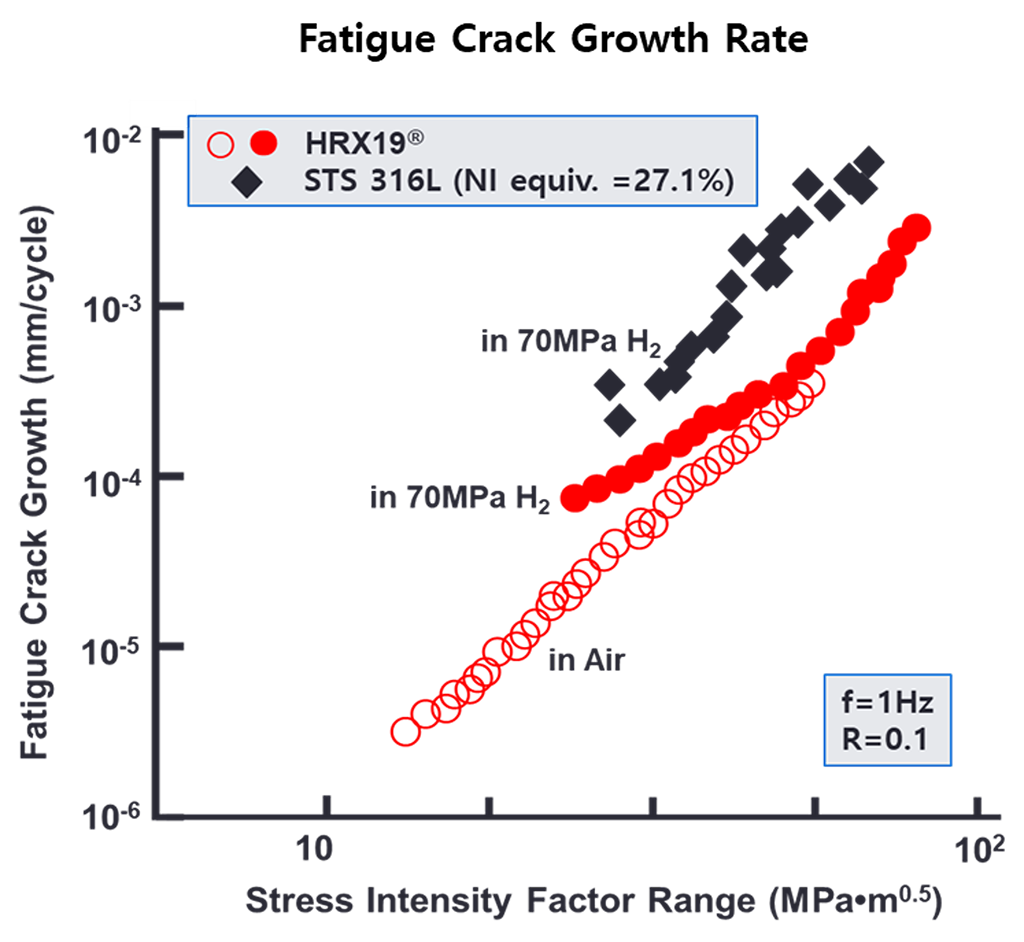

HRX19® Hydrogen embrittlement resistance

- Elongation ratio: in-H2 / in-Air >95%

- Excellent hydrogen embrittlement resistance even at ultra-high pressure (100MPa) and low temperature (-50oC)

- Long-term operation possible -> Reduced maintenance costs